Type: palm fruit/bench oil pressing machine,palm oil making machines

Processing Material: Palm fruit

Processing Capacity: 5-120TPH

Palm oil mill plant flow chart introduction: 1.Palm oil mil process of bunch reception: as palm fruit unloading, cleaning, storage platform during palm oil mill processing, all hydraulic segmented discharge.

2.Palm oil mil process of sterilization: the use of high temperature to cook soft fruit bunches and sterilization, easy to separate fruit bunches, soft fruit, increasing the humidity of the fruit, it is easy to take the oil but also to make verification easier separation of the core-shell, preventing enzymatic decomposition, to avoid elevated levels of free fatty acids.

3.Palm oil mil process of threshing: strong vibrations through the fruit from fruit bunches separated.

4.Crashing.The purpose of crashing is used to separete the pulp and nut and crush the palm pulp.At the same time , the steam is used to cook the palm fruit and broke the cell of pulp.The best condition of cooking is 90~100 for 20 mins.

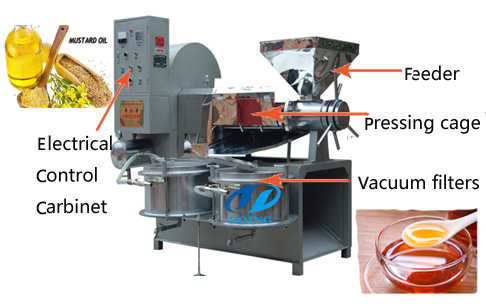

5.Palm oil mil process of pressing:

5.Palm oil mil process of pressing: There is also the steam heater in masher. The purpose of mashing is to separate the pulp and nut and crush the palm pulp. At the same time, the steam is used to cook the palm fruit and broke the cell of pulp.Because of cooking, sterilizing,threshing and mashing made the pulp soft and damage pulp cell structure, the palm pulp becomes soft and cell is broken. Then it is sent to continuous screw press. After pressing, oil palm fruit is divided into two parts:the mixture of oil,water and solid impurities,and the press cake (fiber and nut).The pulp stone separation obtained CPO and stone, press machine adopts the double screw helix continuous discharge and hydraulic, greatly improving production efficiency.

6.Fiber separation. The extrued fiber pie enters air separation system after crushed to get separation of fibers and cores.

7.Separation. Crusher divided fruit core into palm kernel and shell after separated with fiber. Air separation and washing systems separate palm kernels and shells. Shells enters boiler system as fuel, and palm kernels are storage after drying.

8.Palm oil mil process of clarification:

8.Palm oil mil process of clarification: Machine-pressed crude oil first diluted with water washing, through settlement and filtration, the fiber material removed from the oil, and then carry out continuous settlement, the whole divided into two parts: oil and sediment. The oil and the sludge taken out separated (by 90% pure oil) is taken out of the oil containing 45%-55% of the water, sludge and other things.

Any questions about the

palm oil mill plant | palm oil processing machinery,you can visit :

www.doinggroup.com

Contact: Ms Elina

Phone: +86-371-56771822

TEL: +86 155 155 38695

Skype:elina881130

Email:market@doinggroup.com