1.Features of rapeseed oil press machine

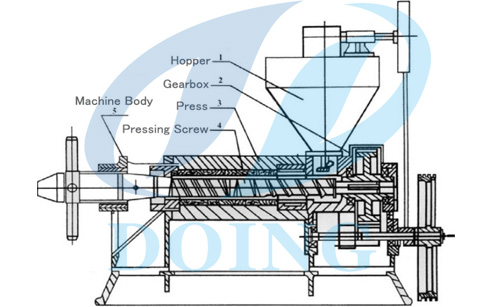

A.Cast iron machine base;

B.Special gear bos structure make the rotating speed averagely;

C.Main parts of charmber through the processing of high-temperature tempering and low temperature quenching;

D.Cake thickness can be adjusted once the machine stop running;

E.Superior grade oil cake;

F.Compact structure, stable function, simple maintenance.

|

| Rapeseed oil press machine |

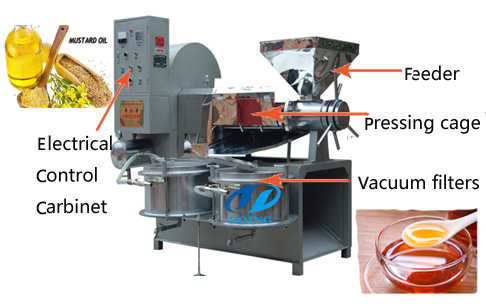

A.oil plants with heavy fiber or shells, or the cakes need to be used as fodder, such as peanut, sesame, corn germ, tung seed, tea seed, palm kernel and any other any nuts.

B.Medium and small oil refinery, oil mill and private oil squeezing workshop.

C.Performs well both in cold pressing and hot pressing.

Any questions about the rapeseed oil press machine ,weclome to contact us.

Contact: Elina

Email : market@doinggroup.com

web: www.doinggroup.com

Tel : 008637156771822